Loop closure grasping: Topological transformations enable strong, gentle, and versatile grasps

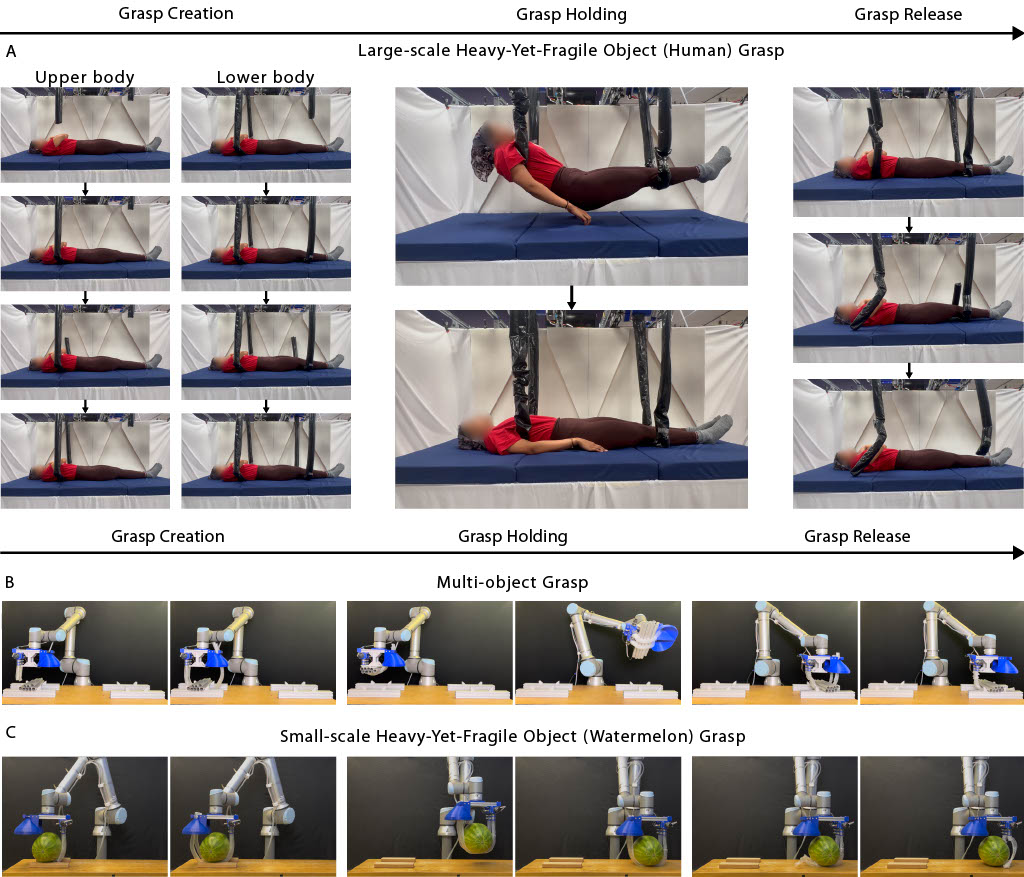

Grasping mechanisms must both create and subsequently hold grasps that permit safe and effective object manipulation. Traditional mechanisms address the different functional requirements of grasp creation and grasp holding using a single morphology, but have yet to achieve the simultaneous strength, gentleness, and versatility needed for many applications. We present “loop closure grasping,” a method of robotic grasping that addresses these different functional requirements through topological transformations between open-loop and closed-loop morphologies. Topologically open-loop mechanisms enable versatile grasp creation via unencumbered tip movement around the object, but lack the simultaneous strength and compliance needed for holding heavy yet fragile objects. Closed-loop mechanisms (e.g., slings) can bear heavy loads in a passive cradled state with effectively infinite bending compliance, but present challenges for grasp creation because the object must somehow enter the loop. Loop closure grasping circumvents the tradeoffs of single-morphology designs by transforming the mechanism’s topology from open-loop to closed-loop between the grasp creation and holding stages. We formalize these morphologies for grasping, formulate the loop closure grasping method, and present a design architecture and implementation using soft growing inflated beams, winches, and clamps. Finally, we demonstrate grasps involving historically challenging objects, environments, and configurations.

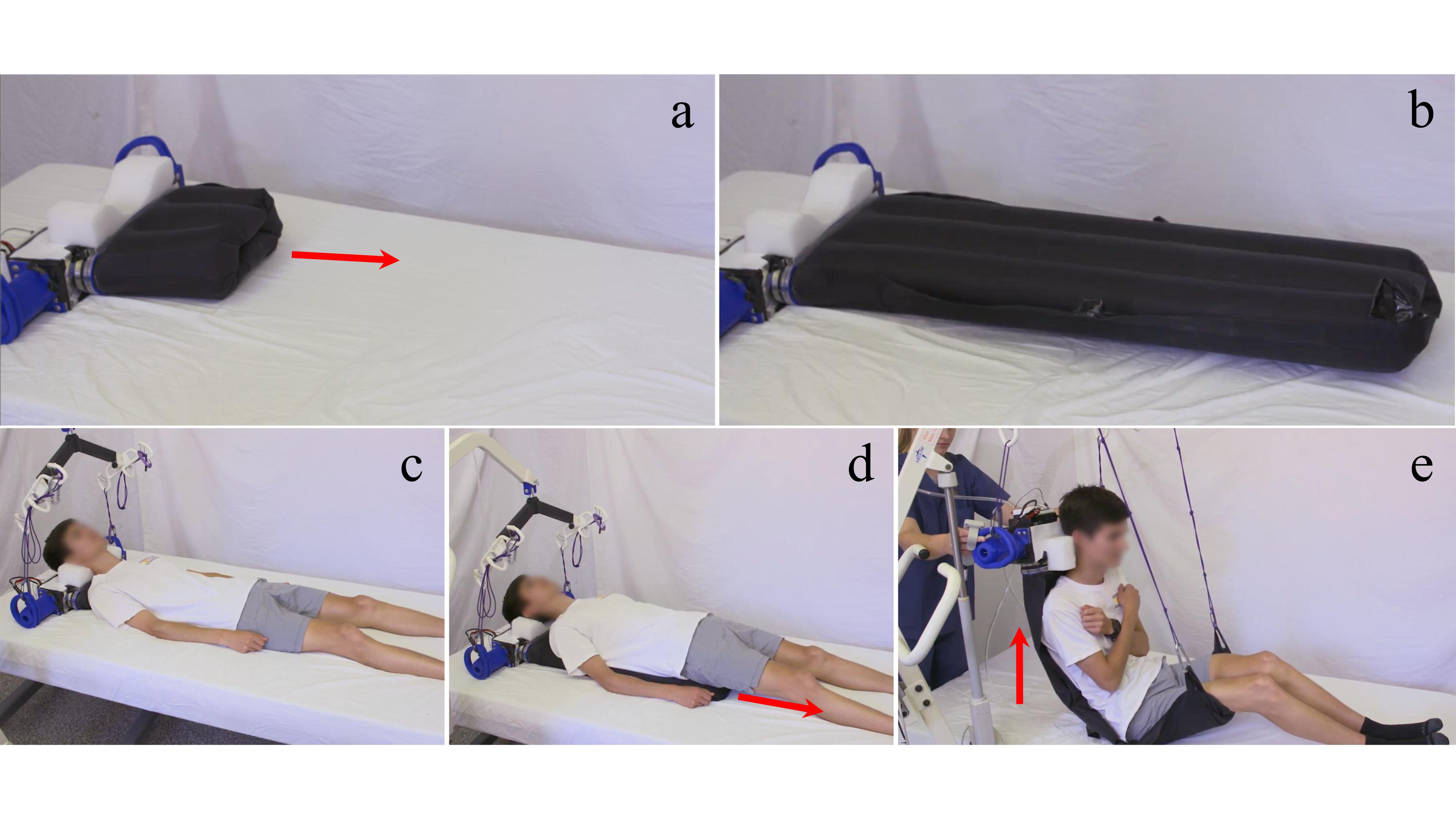

Mechanically Programming the Cross-Sectional Shape of Soft Growing Robotic Structures for Patient Transfer

A method of mechanically programming the cross-section of soft everting robotic structures using flexible strips that constrain radial expansion between points along the outer membrane.

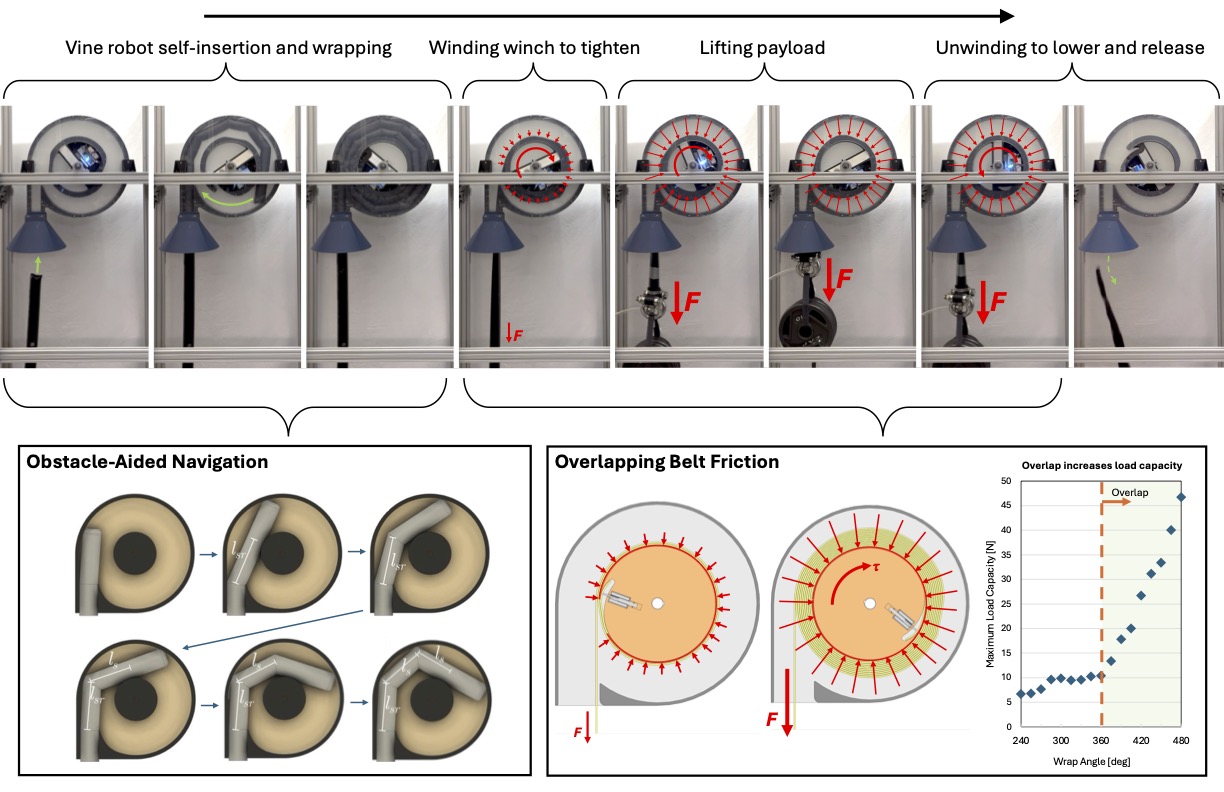

Tip-Clutching Winch for High Tensile Force Application with Soft Growing Robots

Co-designed a device into which vine robots can insert themselves and anchor to via powerful overlapping belt friction

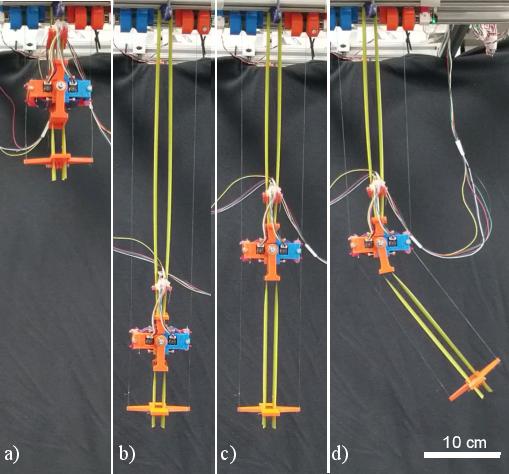

A Lightweight, High-Extension, Planar 3-Degree-of-Freedom Manipulator Using Pinched Tape Springs

Co-designed a lightweight manipulator capable of high extension ratios by locally modifying the transverse curvature of steel tape springs